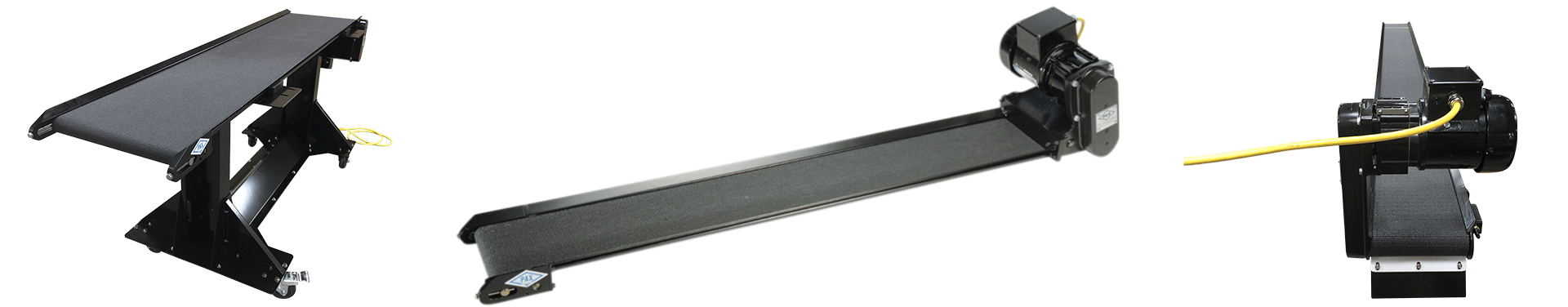

Low Profile Conveyors

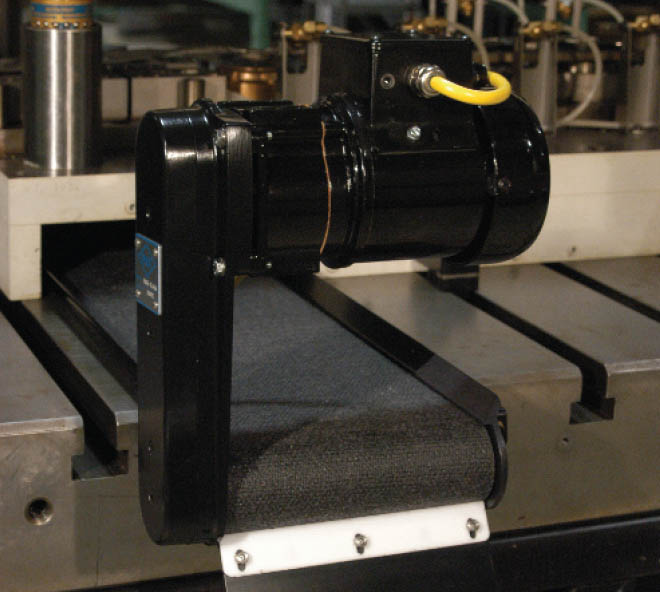

The patented Pax Low Profile Conveyor is specifically designed for on-bolster, under-die parts, and scrap removal. The “low-profile” design enables it to fit where many conveyors will not. Designed by our tool & die craftsmen, the conveyors are built to survive the rough metal stamping environment.

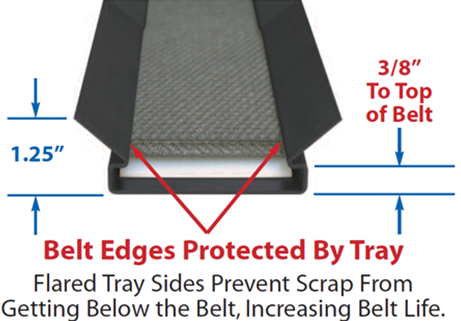

- 3/8” Belt Height

- 2.5” Clearance

- Long Belt Life

- Resistance to Die Lube

Overview

Overview

Pax Low Profile

The patented Pax Low Profile Conveyor is specifically designed for on-bolster, under-die parts, and scrap removal. The “low-profile” design enables it to fit where many conveyors will not.

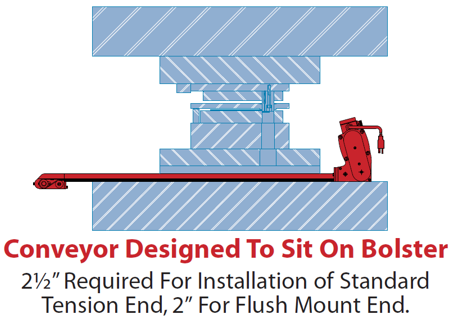

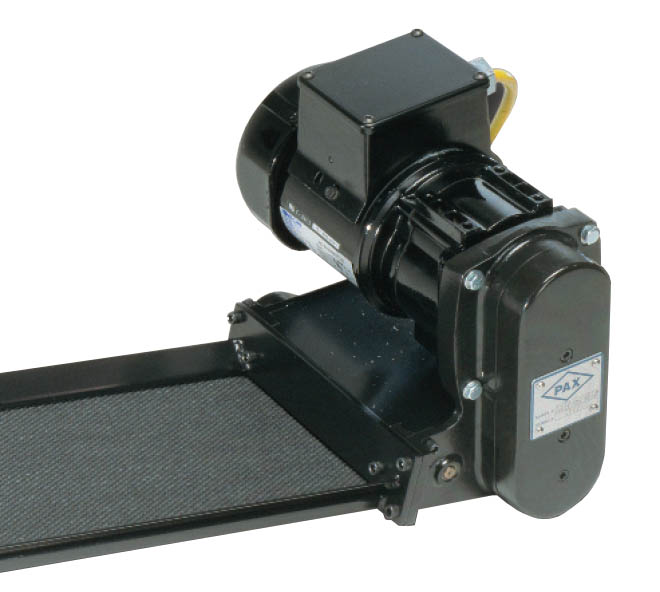

The standard drive arrangement is designed for the motor end of the conveyor to be set on the bolster, inside the bed area of the press. This eliminates the need for extra guarding and does not interfere with existing guarding. Other drive arrangements such as an inverted drive (motor is below the belt), extended top drive (motor is above the belt and parts pass below the motor), and right-angled drives are available as options. The standard tension end is only 2.5” high and is designed to hang over the end of the bolster. An optional flush mount tension end is available for applications where the tension end must lay flat on the bolster.

Resistant To Die Lubrication

Critical Areas Are Sealed to Prevent Die Lube From Entering

Pax Control Box Designed With Gasket Seals

Motor Configurations

Motor Config

Drive Configurations

Standard Top Drive

Designed to sit directly on the press bolster, this drive can often be positioned within existing guarding. With this arrangement, the material must be conveyed away from the motor.

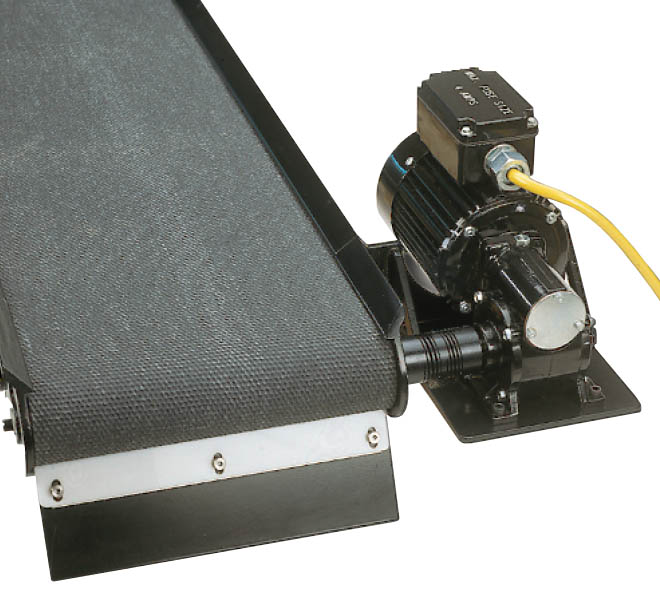

Inverted Drive

The motor hangs below the conveyor tray and the conveyor can be arranged to either move the material towards or away from the motor.

Extended Top Drive

The motor is mounted above the conveyor tray and the conveyor can be arranged to either move the material towards (and under) or away from the motor.

Right Angle Drive

The motor is mounted to the side of the conveyor tray and the conveyor can be arranged to either move the material towards or away from the motor.

Conveyor Belt

Conveyor Belt

Standard Belt

The standard black belt is made of a rugged, woven polyester PVC belt. The belt is connected with stainless steel lacing and pin, and the belt can be changed in less than 5 minutes.

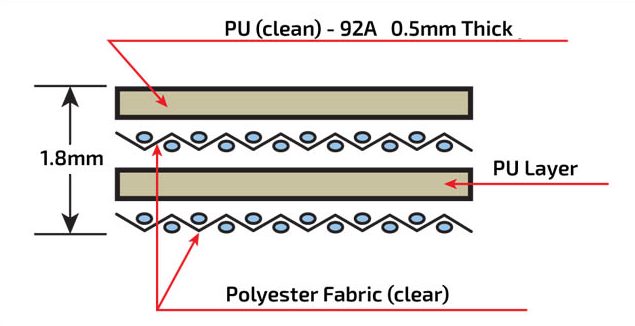

2 Ply Mono-Filament, Urethane belt

This smooth, white belt is oil resistant and is comprised of 2 layers of clear polyurethane and 2 layers of urethane-coated polyester material, which combine for a total thickness of 1.8 mm. This belt design typically lasts 3 to 4 times longer than the standard polyester belt. This belt is available as either an endless belt or can be connected with stainless steel lacing and pin.

Custom Belts

Contact Pax in regards to other belt requirements.

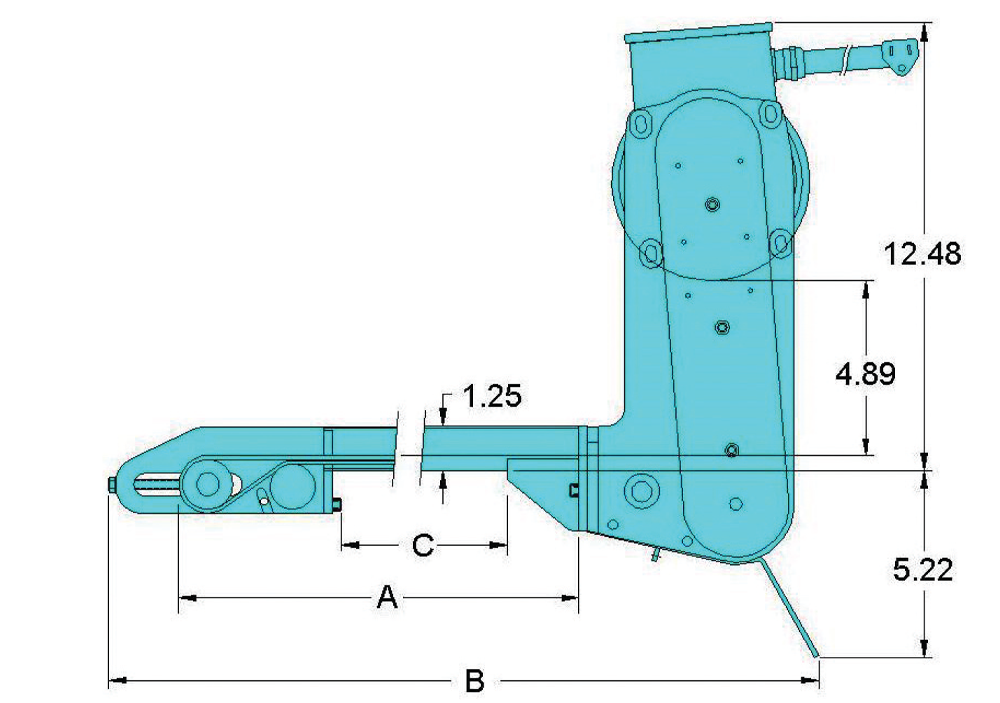

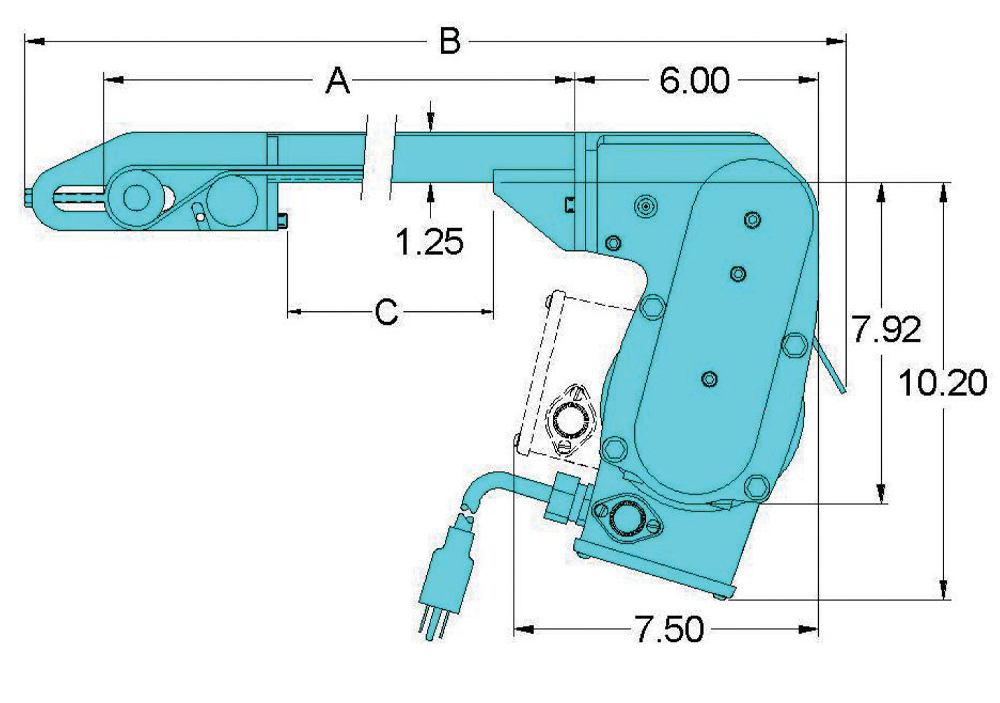

Dimensions and Model Numbers

Dimensions and Model Numbers

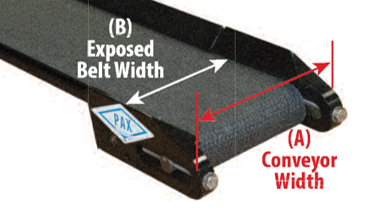

Standard Widths of Low Profile Conveyor:

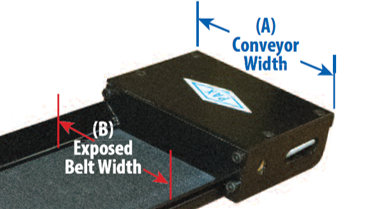

| NOMINAL TENSION END AND BELT WIDTHS | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| *4″ | *5″ | 6″ | 7″ | 8″ | 9″ | 10″ | 12″ | 14″ | 16″ | 18″ | 20″ | |

| Tension End Width (A) | 3.95″ | 4.95″ | 5.95″ | 6.95″ | 7.95″ | 8.95″ | 9.95″ | 11.95″ | 13.95″ | 15.95″ | 17.95″ | 19.95″ |

| Belt Width (B) | 2.35″ | 3.35″ | 4.35″ | 5.35″ | 6.35″ | 7.35″ | 8.35″ | 10.35″ | 12.35″ | 14.35″ | 16.35″ | 18.35″ |

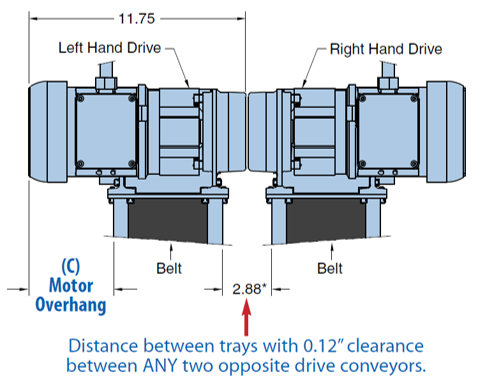

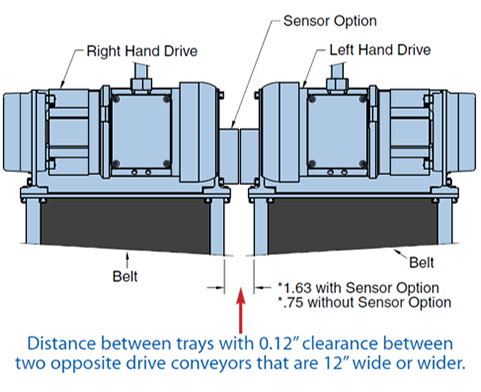

| Distance Motor Extends Beyond Tray (C) ** | 6.56″ | 5.56″ | 4.56″ | 3.56″ | 2.56″ | 1.56″ | 0.56″ | – | – | – | – | – |

Standard Lengths of Low Profile Conveyor: (contact Pax if a custom length is required)

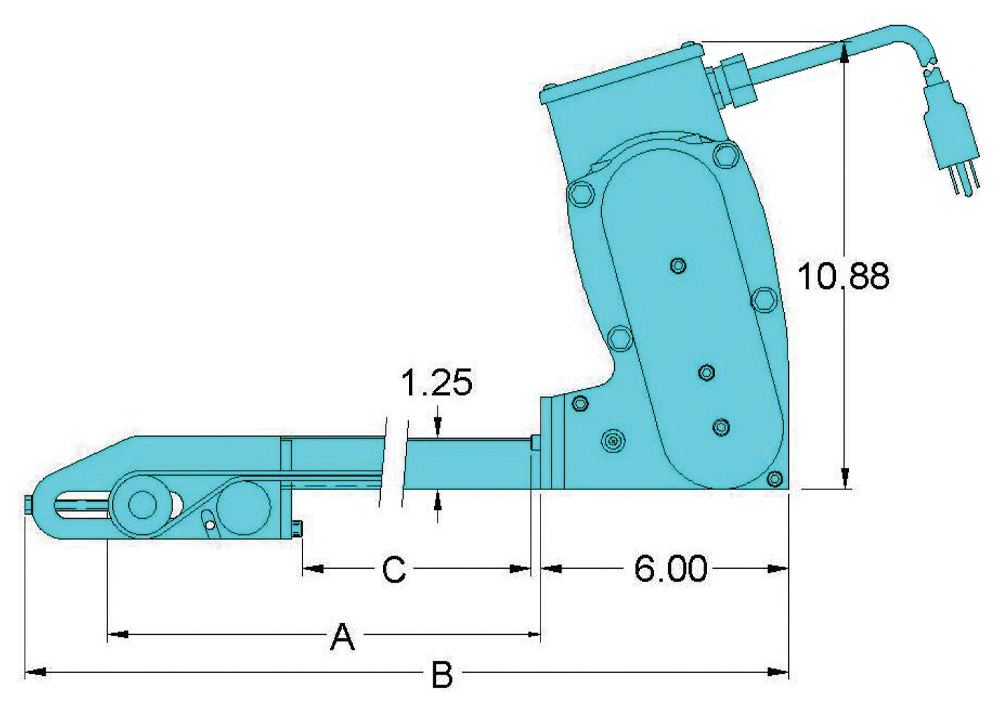

Top Drive

| Normal Length |

Dimension | ||

|---|---|---|---|

| A | B | C | |

| 4′ | 48″ | 56″ | 43.2″ |

| 5′ | 60″ | 68″ | 55.2″ |

| 6′ | 72″ | 80″ | 67.2″ |

| 7′ | 84″ | 92″ | 79.2″ |

| 8′ | 96″ | 104″ | 91.2″ |

Extended Top Drive

| Normal Length |

Dimension | ||

|---|---|---|---|

| A | B | C | |

| 4′ | 48″ | 56″ | 43.2″ |

| 5′ | 60″ | 68″ | 55.2″ |

| 6′ | 72″ | 80″ | 67.2″ |

| 7′ | 84″ | 92″ | 79.2″ |

| 8′ | 96″ | 104″ | 91.2″ |

Inverted Drive

| Normal Length |

Dimension | ||

|---|---|---|---|

| A | B | C | |

| 4′ | 48″ | 56.7″ | 41.5″ |

| 5′ | 60″ | 68.7″ | 53.5″ |

| 6′ | 72″ | 80.7″ | 66.5″ |

| 7′ | 84″ | 92.7″ | 77.5″ |

| 8′ | 96″ | 104.7″ | 89.5″ |

Right Angle Drive

| Normal Length |

Dimension | ||

|---|---|---|---|

| A | B | C | |

| 4′ | 48″ | 56.1″ | 43″ |

| 5′ | 60″ | 68.1″ | 55″ |

| 6′ | 72″ | 80.1″ | 67″ |

| 7′ | 84″ | 92.1″ | 79″ |

| 8′ | 96″ | 104.1″ | 91″ |

Popular Options

Popular Options

Flush Mount Tension End

The flush mount tension end may be required in applications that do not allow the conveyor to be inserted completely through the die. It is also well suited for removing parts and scraping off the end of dies. This option requires the use of either an inverted, extended top, or right-angle drive (belt travel towards the drive end). The overall height of the tension end is reduced to 2.0”.

Stopped Belt Sensor

The stopped belt sensor is used in conjunction with the press control die protection circuit. The press control can stop the press when the signal it is receiving from the stopped belt sensor indicates that the belt has stopped. This prevents or minimizes any damage to your die or conveyor that would have been caused by a stopped belt.

The sensor is available in either of the below arrangements:

Magnetic Based Sensor

utilizes a reed switch to detect magnets that are in a sensor wheel attached to an idler pulley on the conveyor. To use the sensor, the customer must connect the sensor wire to their die protection unit. The die protection unit will supply low-voltage DC current to the sensor. When the reed switch closes (due to the magnetic force of a passing magnet) this current will flow and when the reed switch is open (when the magnet moves away) the current will not flow.

Proximity-Based Stopped Belt Sensor

utilizes a DC, Normally Open, Inductive Proximity Sensor with an M12 threaded body and with a 2-meter long cable with flying leads, which the customer must interface with their press die protection. The standard sensor is NPN but a PNP sensor can be provided if specified at the time of the order.

Self Adjusting Belt Wiper

The wiper greatly reduces the chance of small slugs entering the belt and tray and causing additional problems. This option is available for both the tension end and the drive end of the conveyor. Note: Wiper is standard when the conveyor is ordered with an inverted, extended top, or right angle drive/belt driven toward the motor option.

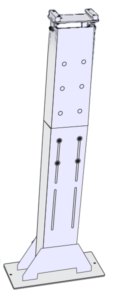

Adjustable Support Stand with Pivoting Top Plate (without Casters):

Pax toe clamps are used to attach the conveyor to this stand. The stand’s top plate is designed such that it can be pivoted, which allows the stand to support the conveyor at an angle if desired. The base of the stand is 24” wide by 8” deep and the stand is designed to sit on and/or be bolted to the floor. The stand is painted black.

Height Ranges:

| Pax Part Number | Height from Floor to Bottom of Conveyor Tray | Height from Floor to Top of Conveyor Tray | ||

|---|---|---|---|---|

| Minimum | Maximum | Minimum | Maximum | |

| 500-5440-0 | 16.0” | 24.0” | 16.4” | 20.4” |

| 500-5441-0 | 21.0” | 28.0” | 21.4” | 28.4” |

| 500-5442-0 | 24.0” | 36.0” | 24.4” | 36.4” |

| 500-5443-0 | 32.0” | 44.0” | 32.4” | 44.4” |

| 500-5444-0 | 36.0” | 56.0” | 36.4” | 56.4” |

Adjustable Support Stand with Casters and Common Base:

Pax toe clamps are used to attach the conveyor to this stand. The stand’s top plates are designed such that they can be pivoted, which allows the stand to support the conveyor at an angle if desired.

The base of the stand is 24” wide and 48” long. Four casters, (two straight and two lockings, swivel casters), which can be bolted to the bottom of the stand, will be provided for each stand. The stand is painted black.

Height Ranges:

| Height from Floor to Bottom of Conveyor Tray |

Height from Floor to Top of Conveyor Tray |

||

|---|---|---|---|

| Minimum | Maximum | Minimum | Maximum |

| 20.7” | 28.7” | 21.1” | 25.1” |

| 25.7” | 32.7” | 26.1” | 33.1” |

| 28.7” | 40.7” | 29.1” | 41.1” |

| 36.7” | 48.7” | 37.1” | 49.1” |

| 40.7” | 60.7” | 41.1” | 61.1” |

Toe Clamp (P/N 500-5638-0)

These clamps can be utilized to attach the conveyor to legs or other fixtures. The clamps are 3” anodized aluminum bars with 1/4 – 20 taps designed to fit over the conveyor rail.

Variable Speed Motor & Control:

The speed range for the standard top drive, inverted drive, and extended top drive conveyors will be 25 to 90 feet/min. The speed range of right-angle drive conveyors will be 25 to 65 feet/min.

With this option, the standard conveyor motor is replaced with a 3-phase motor and a Variable Frequency Drive (VFD). is utilized to start and stop the conveyor.

Grease Gun:

This needle nose grease gun allows you to easily lubricate the conveyor bearings.