Drum Motor Conveyors

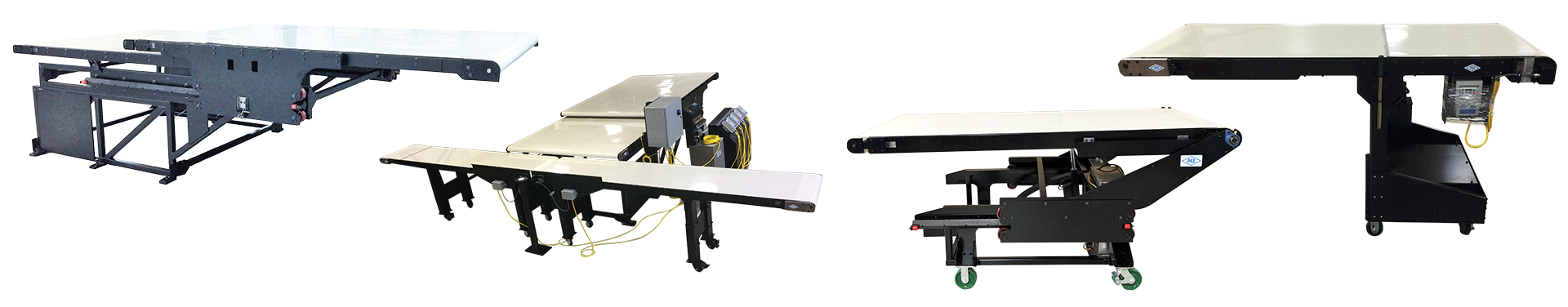

The Pax Model DMC “Drum Motor” Conveyor is designed for removing parts and scrap from dies. This low-maintenance conveyor utilizes a geared motor hermetically sealed inside a steel cylindrical tube. This technology eliminates the need for chains, sprockets, and external motors.

Overview

Overview

Pax Drum Motor Conveyors, (“DMCs”) are rugged, high-capacity, low-maintenance conveyors that utilize motorized pulley design, which eliminates the need for external motors, chains, and sprockets.

- Widths up to 72”

- Low Profile Designs Available

- Speeds over 250 fpm Available

- Options for Cantilevered & Powered Lift and Positioning

- Highly customizable

Conveyor Belt

Conveyor Belt

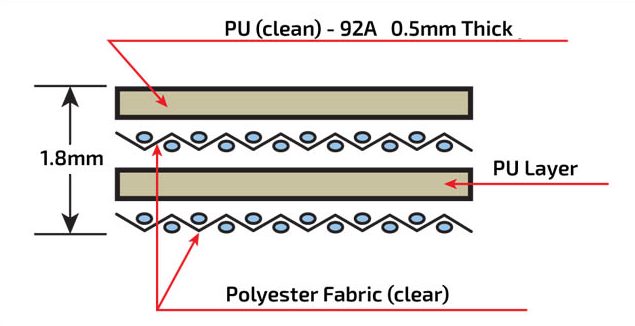

2 Ply Mono-Filament, Urethane belt

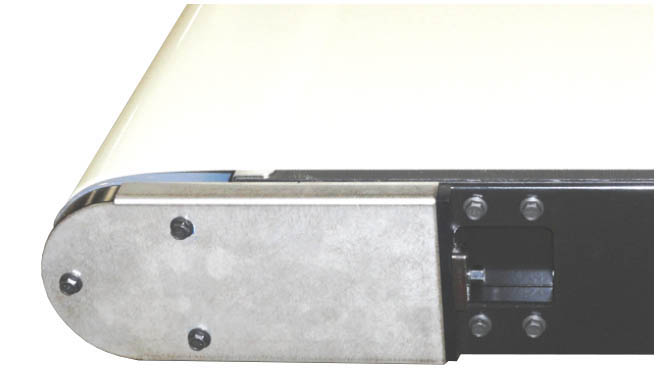

This is the standard belt for the CD conveyor. This smooth, white belt is oil resistant and is comprised of 2 layers of clear polyurethane and 2 layers of urethane-coated polyester material, which combine for a total thickness of 1.8 mm. This belt is connected with stainless steel lacing and a pin.

Custom Belts

Contact Pax in regards to endless belts or belts made from alternate materials.

Specifications

Dimensions of a basic conveyor with a 2.5” diameter Tension Pulley

Standard Speed: 20 to 80 fpm

Max. Avail. Speed: Over 250 fpm

Belt Widths: 12.5” to 72”

Max. Belt Length: 13’ to 20’ depending on conveyor configuration

The below, interactive drawing can be utilized to determine the approximate dimensions of a conveyor that has a 2.5” tension pulley but does not have any options (side rails, stands, etc.). Type in the desired belt width and belt length and the other dimensions will change accordingly.

window.addEventListener(“resize”, Refresh);

function Refresh() {

document.getElementById(“PDF-Container”).innerHTML = ” ;

}

Popular Options

Popular Options

Low Profile and Heavy-Duty Frames

Standard DMC Frame

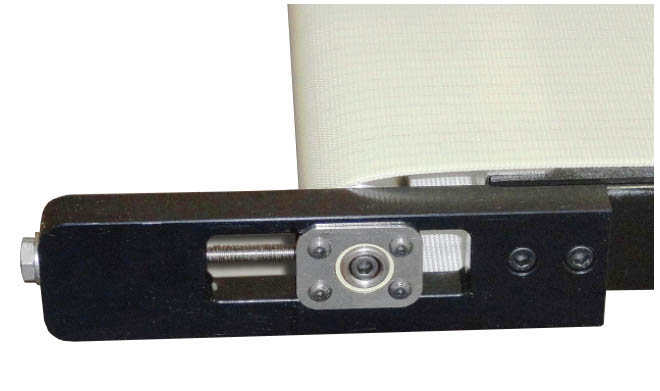

This design is utilized unless an extremely low profile is required or if additional rigidity is required in a large conveyor. This frame utilizes a 2.5” diameter tension pulley and the frame is 3.65” high, (the motor end is 5.14” high). The belt tensioning mechanism does not extend past the conveyor belt, (the belt is flush with the end of the conveyor), and belt tensioning is performed from the back of the tension block.

Heavy Duty Frame

This design is similar to the standard design except a 4.39” tension pulley is used in place of the standard 2.5” pulley and the frame height is increased from 3.65” to 5.2”.

Low Profile Frame

With this design, the height of the conveyor frame is less than 2 inches. To achieve this, plain bearings are utilized in conjunction with a 1.5-inch diameter tension pulley and the belt tensioning mechanism extends past the conveyor belt by 3.1 inches to 5.1 inches. With this design, the maximum width and length of the conveyor, the maximum speed of the conveyor, and the maximum load-carrying capability of the conveyor are reduced.

High Speeds, Fast Start/Stop, & Indexing

In place of the standard geared motor that is sealed in the drive pulley, a Synchronous, Permanent Magnet, (SPM), the motorized pulley can be provided. This arrangement provides:

Speeds of over 250 fpm are available

High Torque Rating throughout the complete Speed Range

0.1 sec. Start/stop Time

Indexing Capability

Potential for Servo Drive Configuration

Cantilever Bases, Legs & Stands

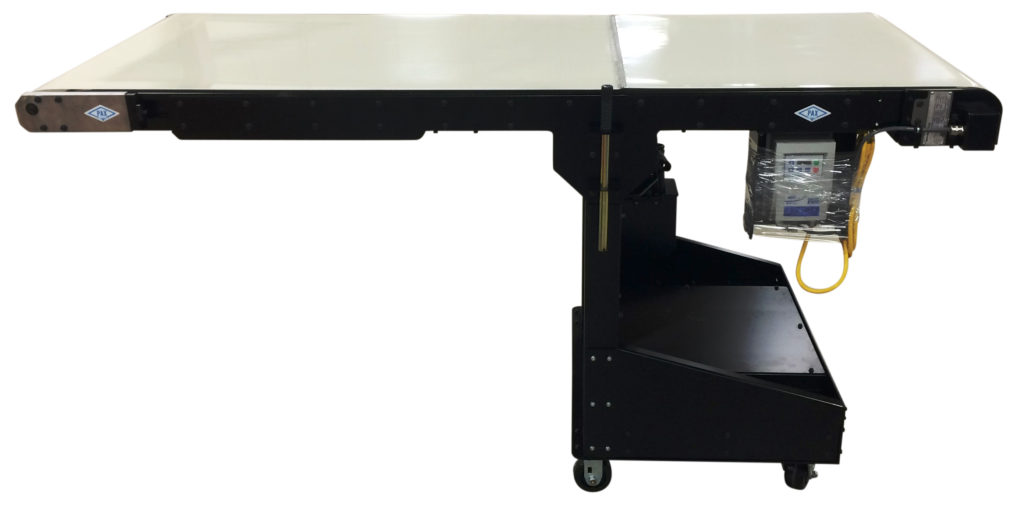

Cantilever Base

This design allows the base of the conveyor to remain out of the press while the entry end of the conveyor extends into the die area, typically through the uprights. As a standard, the height of the conveyor is adjusted via a hydraulic jack but powered height, tilt and horizontal movement options are available.

Legs and stands

A variety of legs and stands are available or can be designed as required. Contact Pax with your requirements.

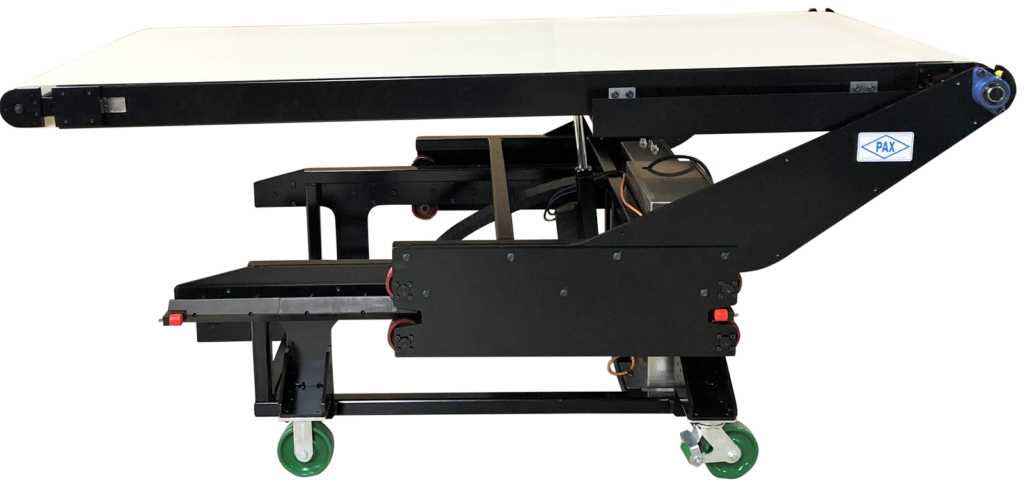

Powered Tilt, Lift, and Horizontal Movement

Products utilize electric, linear actuators to provide individual options for powered tilt, lift, and horizontal movement of the DMC conveyor. These options can be operated via either a jog button or an HMI and they can also be arranged to travel to pre-set positions.

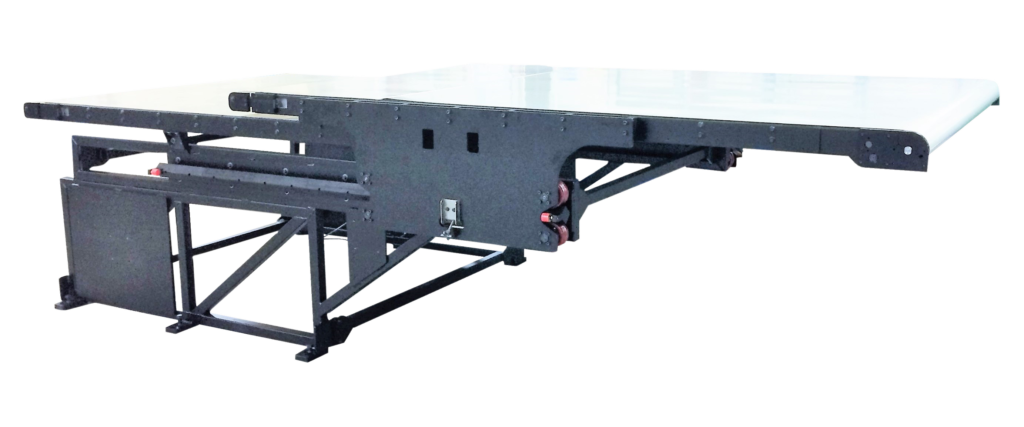

Telescoping (“Stacked”) Conveyors

With this design, the lower, exit conveyor will not move in the horizontal position but the upper, entry conveyor can be extended or retracted as required. The horizontal movement of the upper conveyor can be manual or powered and this feature can be utilized with other powered functions such as tilt capability.

Stopped Belt Sensor

This sensor is typically used in conjunction with the press control die protection circuit. The press control can stop the press when the stopped belt sensor indicates that the conveyor belt has stopped. This arrangement utilizes a 24V DC, normally open, NPN-style proximity sensor with a micro-DC connector. Note: this sensor arrangement will increase the width of the motor end of the conveyor.

Parts Dividers

The standard design is a removable divider that typically is the same length as the conveyor. The position of the divider can be adjusted along the width of the conveyor by loosening the knobs that clamp the divider to the crossbar. The divider assembly can be removed from the conveyor by lifting the cross bars up and out of the brackets that will be bolted to the frame of the conveyor.

Side Rails

Straight, flanged, or custom side rails can be provided as required.