Lube Systems

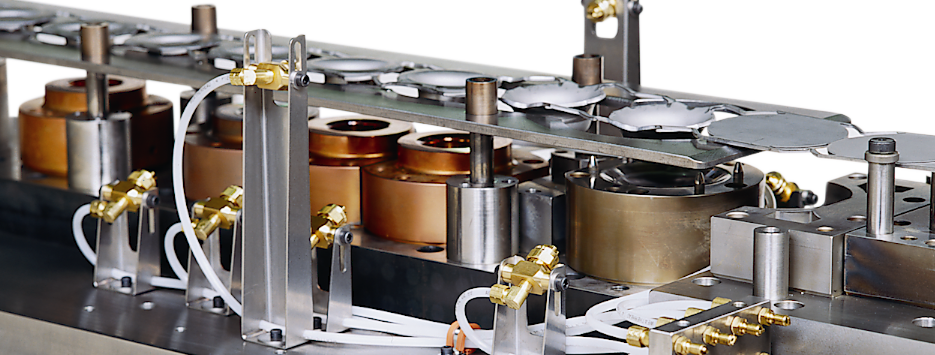

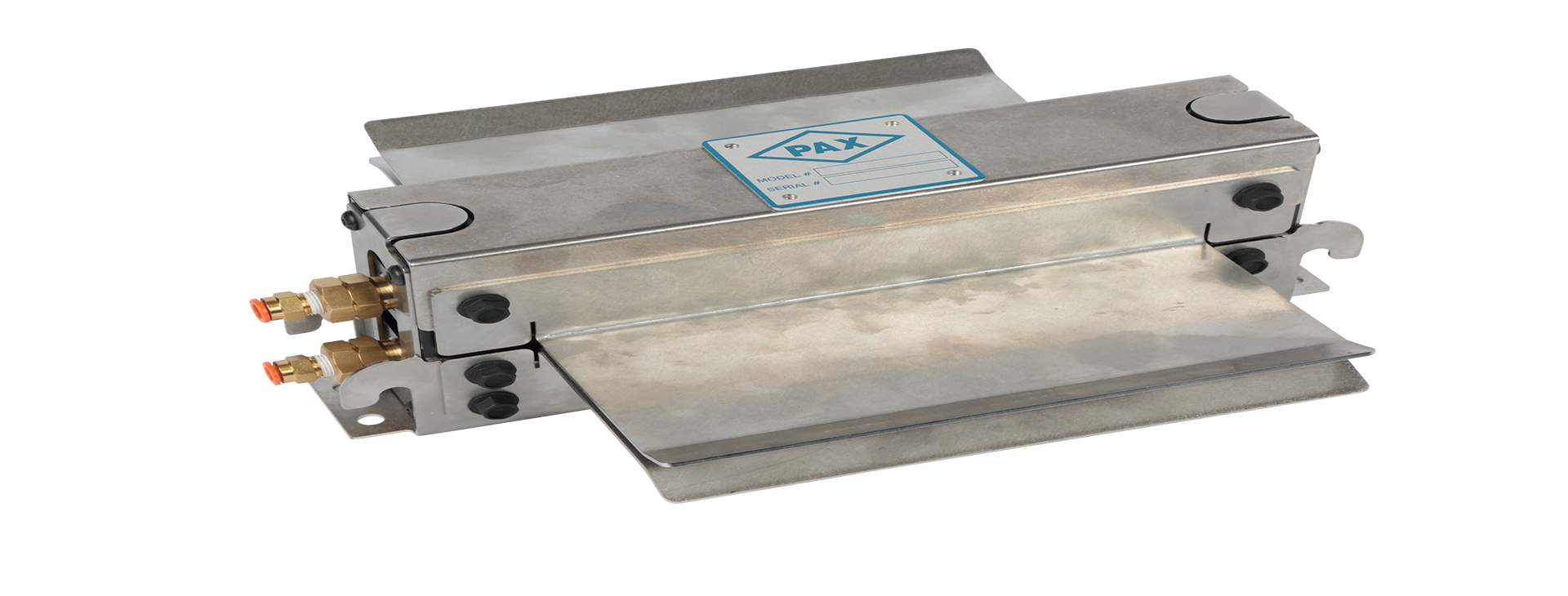

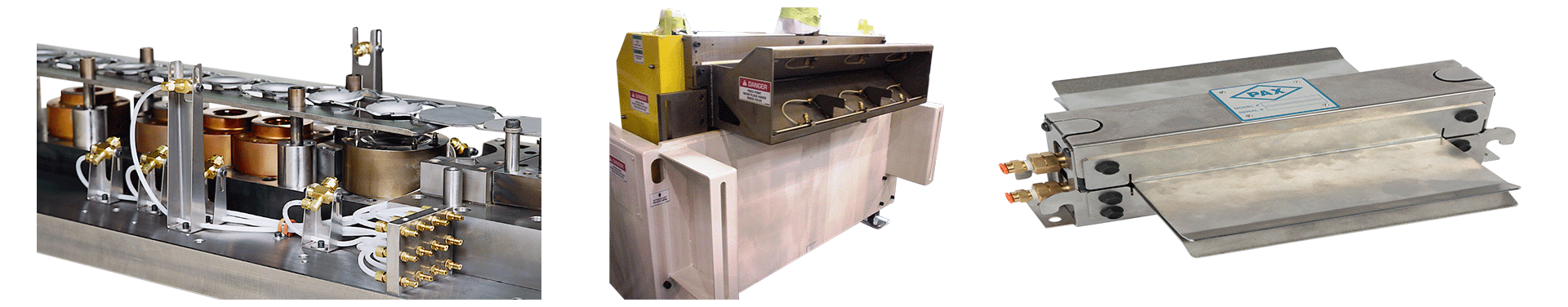

Pax is a pioneer of in-die lubrication. The original Pax system was designed and manufactured in 1975 by skilled tool and die craftsmen and tested in our stamping facility.

By applying only the lubricant needed, only where it is needed, exactly when it is needed, Pax customers have:

- Increased Production Speeds

- Decreased Lube Consumption

- Increased Die Life

- Improved Part Quality

- Improved Working Conditions

All Standard Pax Spray Systems are designed with the following Features:

- “Airless” Spray, which provides better adhesion to the material and less airborne lube than sprays that mix air with the lubricant to better adhere to stock material

- Ability to re-fill system while it is operation

- Arranged to promote lubrication recycling

- No Priming Issues Customized configurations